Resistivity

1-3Ω·cm

Total Assets

Total Land Area

Total Building Area

Silicon Wafer Capacity

Jing Ying Group is headquartered in the core area of the Yangtze River Delta—Zhangjiagang, with a total investment of 2.5 billion yuan. It is a solar photovoltaic enterprise integrating production, research and development, and trade. The holding company, Changshu Fengfan Power Equipment Co., Ltd., is the first professional tower processing and manufacturing enterprise listed on the main board of the Shanghai Stock Exchange (stock abbreviation: Fengfan Co., stock code 601700). It mainly produces various voltage levels (including UHV and EHV) transmission line angle steel towers, steel pipe combination towers, various pipelines, substation structures, as well as steel pipe poles and various steel structural components for various voltage levels.

Focusing on wafer production, continuously refining and specializing, gradually extending to both ends of the industrial chain to create and deliver value for customers.

Through resource integration and technological innovation, based on production specialization, we carry out business diversification;

Win-Win: Win-win with customers, win-win with employees, win-win with shareholders

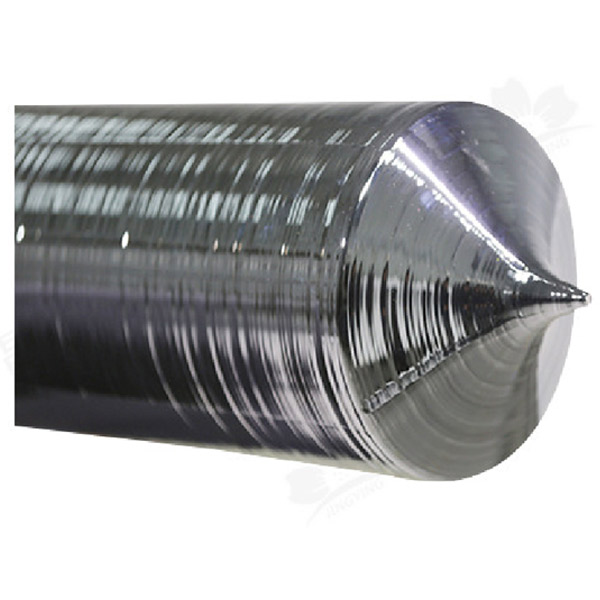

Monocrystalline silicon is a crystal with a basically complete lattice structure. It has different properties in different directions and is a good semiconductor material. Monocrystalline silicon rods are grown from the melt using the Czochralski method or the floating zone method in industrial production. The main indicators include minority carrier lifetime, oxygen content, etc. Monocrystalline silicon rods are the raw material for producing monocrystalline silicon wafers. [Learn more]

1-3Ω·cm

>3μs

≤1*1018at/cm3

≤0.5*1017at/cm3

Products made by directional solidification of silicon materials. Our company produces high-efficiency polycrystalline silicon ingots using the industry's mainstream directional solidification crystal growth method, advanced polycrystalline manufacturing equipment, and independently developed high-efficiency semi melt casting process. The products produced have the characteristics of low impurities, low defects, and high and stable battery conversion efficiency. At present, polycrystalline products have conventional sizes such as 156.75mm and 157mm, and various unconventional size products can also be customized according to customer needs. [Learn more]

1-3Ω·cm

≥6μs

≤5*1017at/cm3

≤7*1017at/cm3

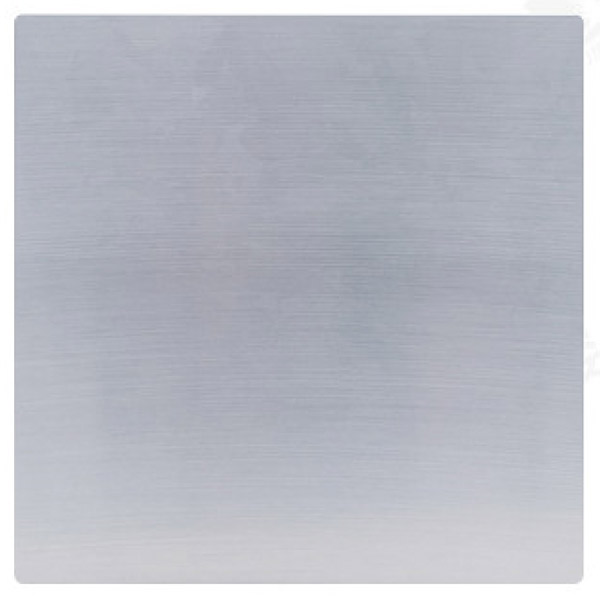

Silicon wafers are the carriers of solar cells. The quality of silicon wafers directly determines the conversion efficiency of solar cells. Our company uses advanced fine wire technology for cutting, ensuring stable product quality. The flatness and breakage rate of the silicon wafers are at the leading level in the industry. [Learn more]

1-3Ω·cm

>3μs

≤0.8*1018at/cm3

≤5*1016at/cm3

Solar cells are currently the fastest-developing type of solar energy cells. Their structure and production processes have been standardized, and the products are widely used in both space and terrestrial applications. These solar cells use high-purity monocrystalline silicon rods as raw materials. To reduce production costs, solar cells for terrestrial applications now use solar-grade monocrystalline silicon rods, with somewhat relaxed material performance indicators. Some may also use head and tail materials and waste monocrystalline silicon materials from semiconductor device processing, which are re-pulled into monocrystalline silicon rods specifically for solar cells. [Learn more]

5 grid lines

60 tablets

265-270W

0`+5%